Work Management

What We Offer

We have devoted years to gaining experience working with maintenance teams of many shapes and sizes in hundreds of manufacturing facilities.

Work Management Process

At the Core of any successful Maintenance program is the ability to effectively plan and execute incoming and existing work. We specialize in working with maintenance teams to improve on the core basics and work flow processes such as:

Work Income and Prioritization

Backlog Management

Job Scoping

Effective Meetings and Communication

Plan, Execute, Follow-Up, Improve

Work Prioritization

Ranking work by priority is essential to making sure the right jobs are getting scheduled when needed. With so many workstream inputs into a maintenance department, this can be a challenged without robust process and tools.

Weekend Work Process

Equipment typically becomes available for maintenance tasks on weekends, holidays, and planned shutdowns. A well planned out and executed weekend plan can greatly reduce equipment failures during a production run.

We specialize in working with maintenance teams giving tools, process, and guidance in achieving the goals

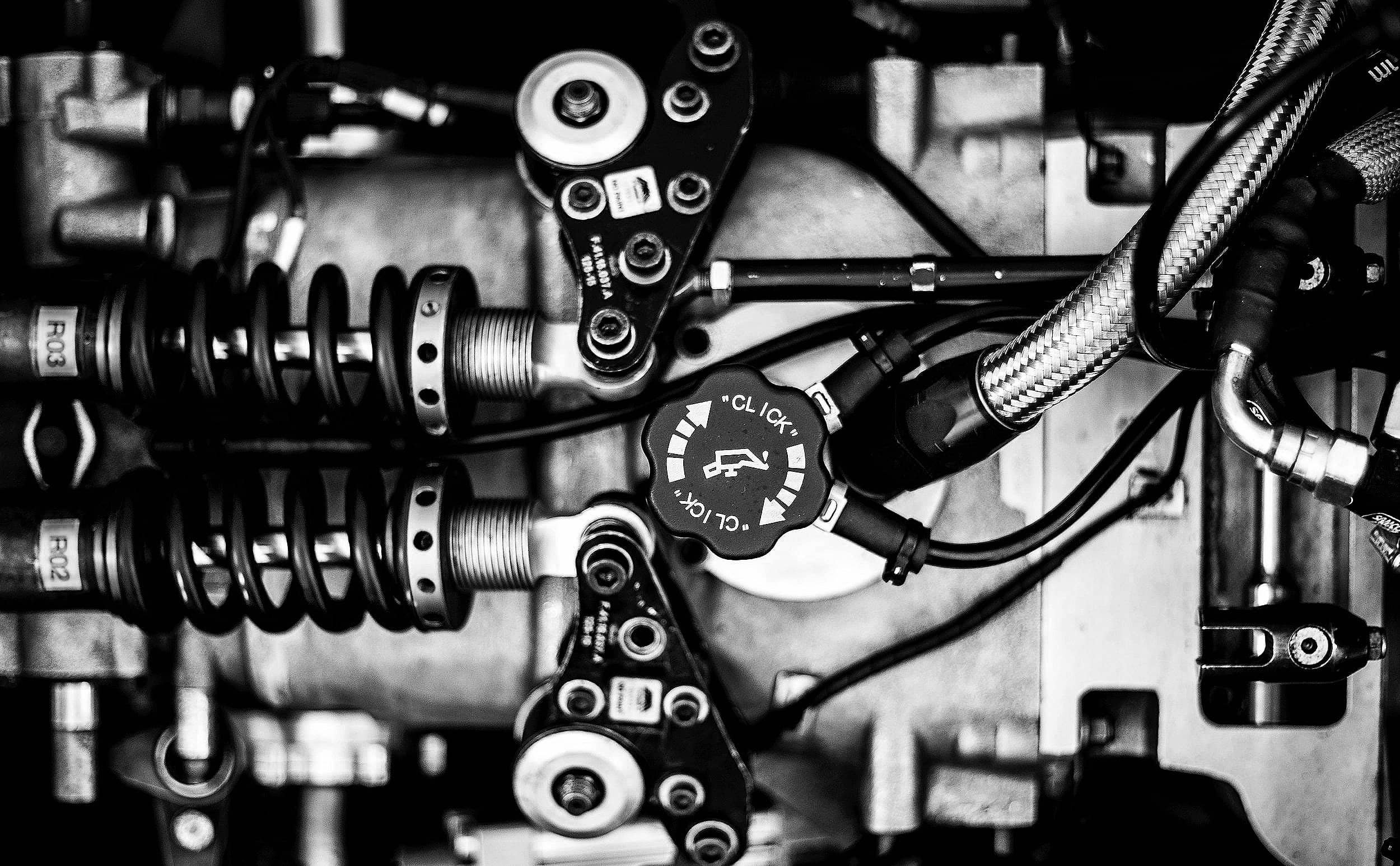

Planned Repairs / Rebuilds

Preventative Maintenance Tasks

Project / Contract Work

Weekend Work

Weekend Work Results